Marine aluminum sheet are typically 5xxx series aluminum-magnesium alloys (such as 5052, 5083, and 5086) or specific 6xxx series alloys like 6061, selected for their superior corrosion resistance, high strength-to-weight ratio, and excellent weldability in harsh marine environments.

Marine aluminum sheet is a specialized aluminum alloy designed for marine applications, valued for its high corrosion resistance, excellent weldability, and light weight.

Common alloys include 5083 and 5052, with 5083 often used for hulls due to its strength and corrosion resistance in seawater, while 5052 is favored for freshwater applications or parts that require more forming.

Other alloys like 6061 are also used for their good strength and processing characteristic

Marine Grade aluminum Sheet Plate has exceptional thermal conductivity and higher strength.

Marine aluminum sheet plate is highly resistant to attack by seawater and industrial chemicals and is very suitable for welding.

In the Marine industry, marine grade aluminum sheet plate is the primary materials for boat hulls and cargo tanks.

Because of Excellent corrosion-resistance and weldability, together with high strength, marine grade aluminum alloy plate sheet was designed for welded structures requiring maximum joint strength and efficiency.

Marine Grade aluminum metal is rated good for forming and weldability, and sufficient for conventional machining applications

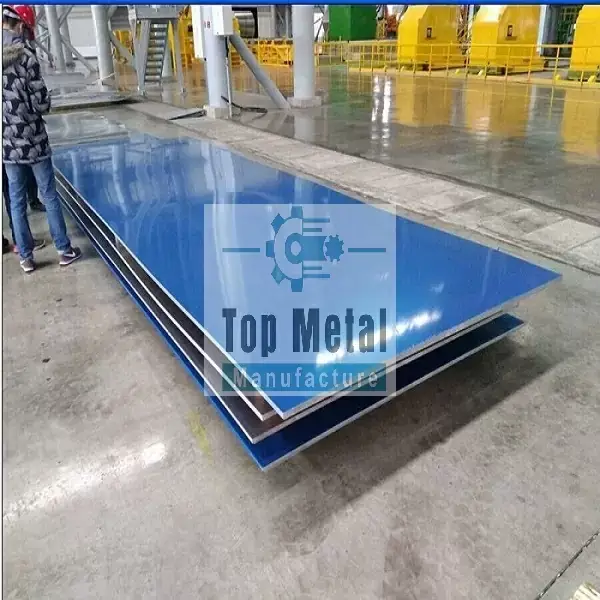

General Marine Grade aluminum plate sheet available

5052 is remarkably resistant to seawater corrosion. Its medium to high strength alloy make-up allow for good cold formability and exceptional weldability. Magnesium is the major alloying element for 5052. In the marine industry, it is the primary material for boat hulls and cargo tanks.

5083

Of all non-heat treatable alloys, this has the highest strength. 5083 is resistant to stress, cracking and exfoliation attack under in marine corrosive conditions. It has a low density and excellent thermal conductivity. It is used across many industries, but primarily shipbuilding.

5086

This alloy shows great results when welded, retaining most of its strength. This factor, along with its corrosion resistance in seawater make it a very popular material choice for the marine industry. 5086 is used extensively for hulls and vessel gangways.

5456

Alloy 5456 is used as a standard application in welded deck house construction of destroyers. It is a preferred material because of the 40-45% weight reduction with no loss of stability. It can be hot worked and has good strength.

6061

This alloy has good weldability and valuable mechanical properties. It is used most often because of these qualities and its strength and workability. It is used most often in deck-house structures, small boats, and bulk-heads.