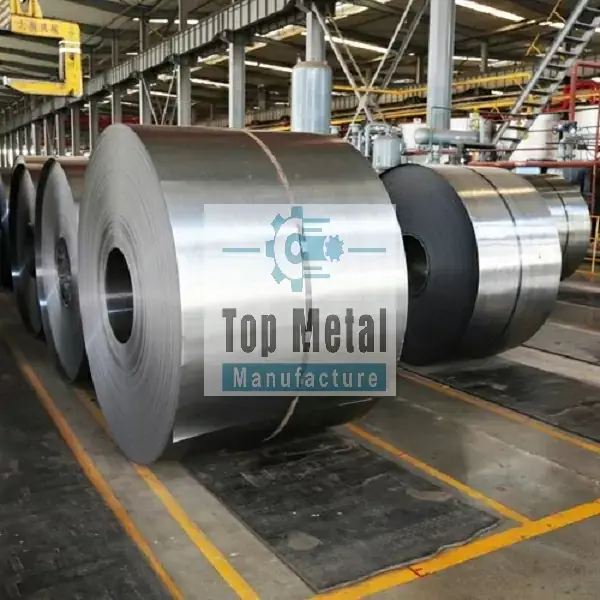

A Cold Rolled Steel Sheet is hot-rolled steel further processed at room temperature for a smoother finish, precise dimensions, and increased strength, making it ideal for automotive parts, appliances, and furnitures, valued for its appearance and formability. This extra processing, which includes rolling below the recrystallization temperature, enhances hardness and yields a clean, uniform surface perfect for painting or coating,

EN 10130 DC01 Steel 1.0330 cold rolled steel sheet coil

DC01 steel (1.0330 material) is a European standard cold-rolled quality low-carbon steel flat product for cold forming. In BS and DIN EN 10130 standard, it contains 5 other steel grades: DC03 (1.0347), DC04 (1.0338), DC05 (1.0312), DC06 ( 1.0873) and DC07 (1.0898), the surface quality is divided into 2 types: DC01-A and DC01-B. In addition, this steel is also used under electrogalvanizing conditions. The designation of the steel is DC01+ZE (or 1.0330+ZE), and the standard is EN 10152.

Cold Rolled Steel Sheet Grade DC01 Meaning and Definition

- D: (Drawing) flat products for cold forming

- C: Cold rolled

- DC01: Drawing quality

- DC03: Deep drawing quality;

- DC04, DC05: Special deepdrawing quality;

- DC06: Extra deepdrawing quality;

- DC07: Super deep drawing quality.

Chemical Composition

DC01 steel chemical composition is listed in the following table based on ladle analysis.

| Country (Region) | Standard | Chemical Composition (ladle analysis), %, ≤ | Surface quality | Deoxidation | Classification | ||||

| Steel name (Steel number) | C | Mn | P | S | |||||

| European Union | EN 10130 | DC01 (1.0330) | 0.12 | 0,60 | 0,045 | 0,045 | A, B | Manufacturer’s discretion | Non-alloy quality steel |

| EN 10152 | DC01+ZE (1.0330+ZE) | A, B | |||||||

| EN 10139 | DC01-C390, C340, C440, C490, C590, C690 | – | |||||||

Notes:

- EN 10130 – Cold rolled low carbon steel flat products;

- EN 10152 – Electrolytically zinc coated cold rolled steel flat products.

- EN 10139 – Cold rolled uncoated low carbon steel narrow strip.

- Cold-rolled steel coils are widely applied to automobiles, electrical appliances, steel office equipment, containers, and numerous other products closely connected to pour daily lives.

| JIS G3141 Chemical Composition | |||||

|---|---|---|---|---|---|

| Material Grade | Chemical Composition % | ||||

| C | Mn | P | S | Alta | |

| SPCC | ≤0.12 | ≤0.50 | ≤0.035 | ≤0.025 | ≥0.020 |

| SPCD | ≤0.10 | ≤0.45 | ≤0.030 | ≤0.025 | ≥0.020 |

| SPCE | ≤0.08 | ≤0.40 | ≤0.025 | ≤0.020 | ≥0.020 |

| for all steel grades,when C≤0.01,Alt≥0.015 | |||||

| JIS G3141 Mechanical Property | ||||||

|---|---|---|---|---|---|---|

| Steel Grade | Tensile test | r90 | n90 | |||

| Yield strength/MPa | Tensile Strength /MPa | Elongation after break b(L0=50mm, b=25mm)/% | ||||

| 0.5~1.0mm | 1.0~2.0mm | not less than | ||||

| SPCC | 140~280 | ≧270 | ≧34 | ≧37 | ||

| SPCD | 140~240 | ≧270 | ≧36 | ≧39 | 1.3 | |

| SPCE | 130~210 | ≧270 | ≧38 | ≧41 | 1.6 | 0.18 |