DC01 es una placa y tira de acero laminadas en frío y con bajo contenido de carbono. Estándar europeo Grado DC01 Fleje de acero laminado en frío es similar al estándar japonés SPCC y al estándar DIN ST12.Dc01 es un estándar europeo, que utiliza el estándar empresarial Baosteel Q/BQB402 o el estándar de la UE EN10130, que es equivalente a la placa laminada en frío de acero 10 en acero estructural al carbono de alta calidad GB699. con un contenido de carbono de aproximadamente 0,10%.

SPCC, S significa para acero, P significa para placa, C significa para laminado en frío, C significa para común. Condición de tratamiento térmico: recocido A, recocido S + liso, dureza 8-(1/8), dureza 4-(1/4), dureza 2-(1/2), dureza 1. Nivel de ductilidad a la tracción: ZF: para las piezas más complejas de acuñar el dibujo. HF: se utiliza para perforar las piezas del dibujo es muy complejo. F: se utiliza para perforar las piezas complejas del dibujo. Para las listas de especificaciones de láminas y tiras de acero SPCC, el espesor es de 0,3 a 3,5. Nuestra empresa dispone de mm y anchos de 120 a 1850 mm. Para la longitud, podemos ofrecerlo según sus requisitos. El acero SPCC tiene una superficie lisa, buen procesamiento, se utiliza principalmente en automóviles, refrigeradores, lavadoras y otros aparatos eléctricos y equipos industriales. Cuanta más información sobre el acero SPCC se muestra en la siguiente tabla Composición química de SPCC

Estándar: JIS, ASTM, EN10130

Grado: SPCC, SPCD, ST12, ST13, ST14/16, DC01, DC02, DC03, DC04, DC05, DC06, Q195, Q195L, SAE1008, SAE1006

brillo / acabado negro blando, duro, trabajado en acero inoxidable Fleje / Flejes de acero laminado en frío:

máx. Ancho (borde del molino): 720 mm

mín. Ancho (borde hendido): 39 mm

máx. Espesor: 2,0 mm

mín. Grosor: 0,3mm

Diámetro interior: 400 mm o 508 mm

Diámetro exterior: 850~1500mm

Forma de la superficie de recocido: brillo y acabado superficial negro.

Carbón laminado en frío SAE 1008 Bobinas de acero con dureza total se utilizan principalmente en automóviles, cubos de metal impreso, construcción, materiales de construcción y bicicletas, etc. Además, es el mejor material para fabricar tiras recubiertas orgánicas.

Composición química

La composición química del acero DC01 se enumera en la siguiente tabla según el análisis de la cuchara.

| País (Región) | Estándar | Composición química (análisis en cucharón), %, ≤ | Calidad de la superficie | Desoxidación | Clasificación | ||||

| Nombre de acero (Número de acero) | C | Minnesota | PAG | S | |||||

| unión Europea | ES 10130 | DC01 (1.0330) | 0.12 | 0,60 | 0,045 | 0,045 | un, b | discreción del fabricante | Acero de calidad sin alear |

| ES 10152 | DC01+ZE (1.0330+ZE) | un, b | |||||||

| ES 10139 | DC01-C390, C340, C440, C490, C590, C690 | – | |||||||

Notas:

- EN 10130 – Productos planos de acero bajo en carbono laminados en frío;

- EN 10152 – Productos planos de acero laminados en frío electrolíticamente cincados.

- EN 10139 – Fleje estrecho de acero bajo en carbono sin recubrimiento laminado en frío.

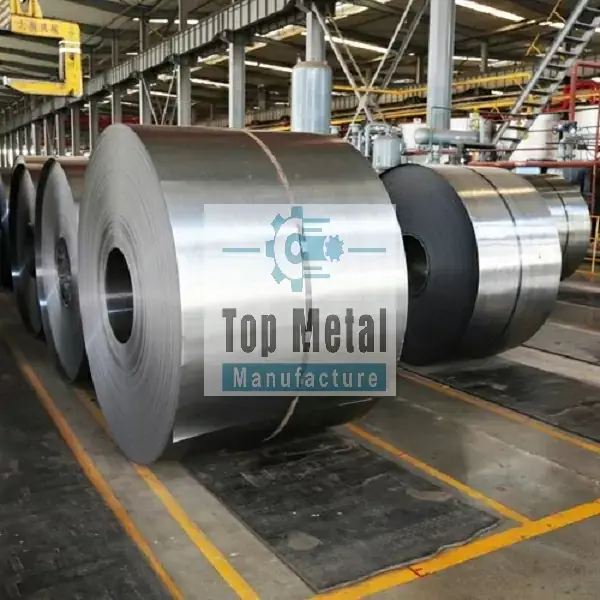

- Las bobinas de acero laminado en frío se aplican ampliamente a automóviles, electrodomésticos, equipos de oficina de acero, contenedores y muchos otros productos estrechamente relacionados con la vida cotidiana.

| Composición química JIS G3141 | |||||

|---|---|---|---|---|---|

| Grado del material | Composición química % | ||||

| C | Minnesota | PAG | S | Alta | |

| SPCC | ≤0.12 | ≤0.50 | ≤0.035 | ≤0.025 | ≥0.020 |

| SPCD | ≤0.10 | ≤0.45 | ≤0.030 | ≤0.025 | ≥0.020 |

| ESPACIO | ≤0.08 | ≤0.40 | ≤0.025 | ≤0.020 | ≥0.020 |

| para todos los grados de acero, cuando C≤0.01,Alt≥0.015 | |||||

| Propiedad mecánica JIS G3141 | ||||||

|---|---|---|---|---|---|---|

| Grado de acero | Ensayo de tracción | r90 | n90 | |||

| Límite elástico/MPa | Resistencia a la tracción /MPa | Alargamiento después de la rotura b(L0=50mm, b=25mm)/% | ||||

| 0,5 ~ 1,0 mm | 1,0 ~ 2,0 mm | no menos que | ||||

| SPCC | 140~280 | ≧270 | ≧34 | ≧37 | ||

| SPCD | 140~240 | ≧270 | ≧36 | ≧39 | 1.3 | |

| ESPACIO | 130~210 | ≧270 | ≧38 | ≧41 | 1.6 | 0.18 |

DC01 se utiliza ampliamente en la fabricación de automóviles, principalmente en la fabricación de chasis de automóviles, sistemas de suspensión, sistemas de frenos, soportes de asientos y otras piezas. Debido a sus excelentes características de rendimiento, puede mejorar la confiabilidad, seguridad y comodidad de los automóviles.

DC01 también se usa ampliamente en la fabricación de electrodomésticos, como electrodomésticos, equipos de comunicación y productos electrónicos, etc.

Debido a sus buenas propiedades mecánicas y propiedades de procesamiento, DC01 se utiliza principalmente para fabricar diversos soportes, carcasas, piezas estructurales y otras piezas clave.

En la fabricación de aires acondicionados, DC01 se puede utilizar para fabricar componentes clave, como soportes de refrigerante y fijaciones de conductos de aire, mejorando la vida útil y la estabilidad de los aires acondicionados.