DC01 est une plaque d'acier à faible teneur en carbone et une bande d'acier laminées en continu à froid. Norme européenne Grade DC01 Bande d'acier laminée à froid est similaire à la norme japonaise SPCC et à la norme DIN ST12.Dc01 est une norme européenne, utilisant la norme d'entreprise Baosteel Q/BQB402 ou la norme européenne EN10130, qui est équivalente à la tôle laminée à froid de 10 aciers en acier de construction au carbone de haute qualité GB699, avec une teneur en carbone d'environ 0,10%.

SPCC, S signifie pour l'acier, P signifie pour les tôles, C signifie pour laminé à froid, C signifie pour le commun. Condition de traitement thermique : recuit A, recuit S + lisse, dureté 8-(1/8), dureté 4-(1/4), dureté 2-(1/2), dureté 1. Niveau de ductilité en traction : ZF-Pour les pièces les plus complexes du dessinHF-Utilisé pour poinçonner les pièces du dessin est très complexeF-Utilisé pour poinçonner les pièces complexes du dessin Pour les listes de spécifications de tôles d'acier et de bandes d'acier SPCC, l'épaisseur de 0,3 à 3,5 mm et largeur de 120 à 1850 mm sont tous disponibles par notre société. Pour la longueur, nous pouvons vous proposer selon vos besoins. L'acier SPCC a une surface lisse, un bon traitement, il est principalement utilisé dans les voitures, les réfrigérateurs, les machines à laver et autres appareils électriques, ainsi que dans les équipements industriels. Plus d'informations sur l'acier SPCC sont présentées dans le tableau suivant Composition chimique SPCC

Norme : JIS, ASTM, EN10130

Catégorie : SPCC, SPCD, ST12, ST13, ST14/16, DC01, DC02, DC03, DC04, DC05, DC06, Q195, Q195L, SAE1008, SAE1006

brillance / finition noire douce, dure, acier inoxydable travaillé Bande / Bandes d'acier laminées à froid :

Max. Largeur (bord de moulin): 720 mm

Min. Largeur (bord fendu) : 39 mm

Max. Épaisseur : 2,0 mm

Min. Épaisseur : 0,3 mm

Diamètre intérieur : 400 mm ou 508 mm

Diamètre extérieur : 850~1500mm

Forme de surface recuite : brillance et finition de surface noire

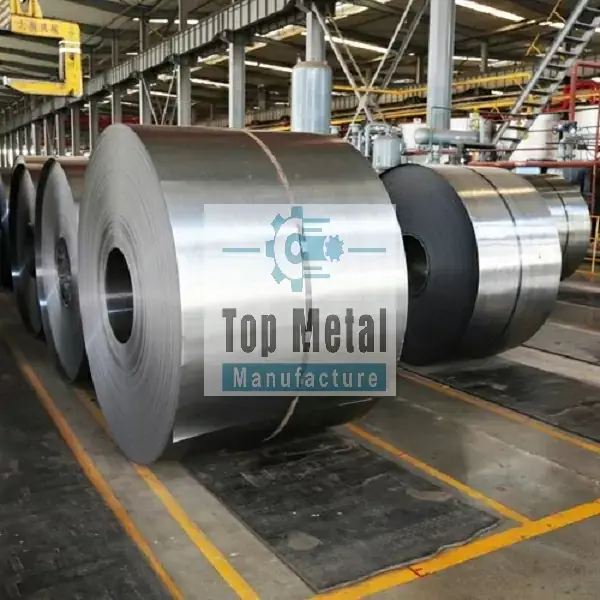

Carbone laminé à froid SAE 1008 Des bobines d'acier avec du dur complet sont principalement utilisés dans l'automobile, les seaux en métal imprimé, la construction, les matériaux de construction et les vélos, etc. De plus, c'est le meilleur matériau pour fabriquer des bandes à revêtement organique.

Composition chimique

La composition chimique de l'acier DC01 est répertoriée dans le tableau suivant sur la base d'une analyse en poche.

| Pays (Région) | Standard | Composition chimique (analyse en poche), %, ≤ | Qualité de surface | Désoxydation | Classification | ||||

| Nom de l'acier (numéro de l'acier) | C | Mn | P | S | |||||

| Union européenne | EN 10130 | DC01 (1.0330) | 0.12 | 0,60 | 0,045 | 0,045 | UN B | La discrétion du fabricant | Acier de qualité non allié |

| EN 10152 | DC01+ZE (1.0330+ZE) | UN B | |||||||

| EN 10139 | DC01-C390, C340, C440, C490, C590, C690 | – | |||||||

Remarques:

- EN 10130 – Produits plats laminés à froid en acier à faible teneur en carbone ;

- EN 10152 – Produits plats en acier laminés à froid électrolytiquement zingués.

- EN 10139 – Bandes étroites en acier à bas carbone non revêtues laminées à froid.

- Les bobines d'acier laminées à froid sont largement appliquées aux automobiles, aux appareils électriques, aux équipements de bureau en acier, aux conteneurs et à de nombreux autres produits étroitement liés à la vie quotidienne.

| JIS G3141 Composition chimique | |||||

|---|---|---|---|---|---|

| Qualité matérielle | Composition chimique % | ||||

| C | Mn | P | S | Haute | |

| SPCC | ≤0.12 | ≤0,50 | ≤0,035 | ≤0,025 | ≥0.020 |

| SPCD | ≤0.10 | ≤0,45 | ≤0,030 | ≤0,025 | ≥0.020 |

| SPCE | ≤0.08 | ≤0.40 | ≤0,025 | ≤0,020 | ≥0.020 |

| pour toutes les nuances d'acier, lorsque C≤0.01, Alt≥0.015 | |||||

| Propriété mécanique JIS G3141 | ||||||

|---|---|---|---|---|---|---|

| Nuance d'acier | Essai de traction | r90 | n90 | |||

| Limite d'élasticité/MPa | Résistance à la traction /MPa | Allongement après rupture b(L0=50mm, b=25mm)/% | ||||

| 0.5~1.0mm | 1.0~2.0mm | pas moins que | ||||

| SPCC | 140~280 | ≧270 | ≧34 | ≧37 | ||

| SPCD | 140~240 | ≧270 | ≧36 | ≧39 | 1.3 | |

| SPCE | 130~210 | ≧270 | ≧38 | ≧41 | 1.6 | 0.18 |

Le DC01 est largement utilisé dans la fabrication automobile, principalement dans la fabrication de châssis automobiles, de systèmes de suspension, de systèmes de freinage, de supports de siège et d'autres pièces. Grâce à ses excellentes caractéristiques de performance, il peut améliorer la fiabilité, la sécurité et le confort des automobiles.

Le DC01 est également largement utilisé dans la fabrication d’appareils électriques, tels que les appareils électroménagers, les équipements de communication et les produits électroniques, etc.

En raison de ses bonnes propriétés mécaniques et propriétés de traitement, DC01 est principalement utilisé pour fabriquer divers supports, coques, pièces structurelles et autres pièces clés.

Dans la fabrication de climatiseurs, le DC01 peut être utilisé pour fabriquer des composants clés tels que des supports de réfrigérant et des fixations de conduits d'air, améliorant ainsi la durée de vie et la stabilité des climatiseurs.